We’ve shared the top things that will likely bust your construction budget in the current commercial landscape. But what about your schedule? Making timely decisions, verifying existing equipment is operational prior to your lease agreement and submitting your permit as early as possible are just a few of the ways you can set your project schedule up for sucess despite today’s increased lead times.

Below is our full guide on how you can get and stay on schedule.

1) Make timely decisions.

To keep to a schedule, nothing helps more than making decisions on time, every time. Late decisions not only delay your project but can also result in penalties for missing your space’s move in or move out date. Knowing that real estate timeline takes up and influences the majority of a project’s lifecycle is crucial in allowing adequate time for the design, documentation and construction stages.

2) The early bird really does get the worm.

These are the elements of a project that should be done earlier rather than later:

- Order IT, audio/video equipment and furniture right away. As these items have lead times over a year or more, it is critical to order these components ASAP and to confirm infrastructure components.

- Get executive input and approval early. To avoid unnecessary delays, ensure the key decision makers are aligned on a project’s design, budget, and construction process so they are able to approve decisions quickly and if possible, ahead of schedule.

- Submit your permit as soon as you’re able. The City of Dallas continues to have unprecedented delays for building and life safety permits, so submitting your permit as soon as possible reduces your chances of going off schedule.

- Don’t wait to verify critical life safety material and equipment availability. These include, but are not limited to, fire alarms and strobe devices. Confirming these items are nonnegotiable.

3) Verify existing equipment is operational prior to lease agreement.

Below are important questions to consider in a few different categories:

- Plumbing – Are there existing drainage issues? Are there pipes that are corroded in the walls? Have other tenants had issues?

- HVAC – How old are your terminal units? How much control do you want? Should you reuse equipment at all?

- BMS Controls – Do they have them? Does the building require a digital controls upgrade? Do you have to buy extra equipment to make this work?

- Electrical Gear/Generator – Have these been inspected lately? When was the last finish out? What is similar occupant density to the new design?

4) Confirm existing conditions onsite through a site survey instead of relying on as-builts or existing documents.

Run through this checklist when analyzing your project’s architectural design:

- Have your consultants been onsite to look above the ceiling and open the mechanical room?

- Are the deck heights and ceiling heights verified?

- Have the base building window coverings been examined?

- Are there irregularities in the current space that could affect design or layout?

5) Create a contingency plan.

Even in the simplest projects, unforeseeable issues can occur. Addressing these three areas can help mitigate any negative impacts:

- Ceiling conflicts – For new designs like unique ceiling features and specialty lighting, there will likely be issues with duct work that require some level of modification. The solution? Letting the team check these areas above the ceiling beforehand.

- Flooring conditions – Know the answers to the following questions:

- Does the building have a history of floor-leveling issues?

- Do the materials planned for install have a tight tolerance such as demountable or operable walls, large format tile and terrazzo?

- If you have a slab on grade, have moisture tests been completed?

- Is there a moisture vapor barrier or some other special slab condition that will affect your finish material install or its warranty?

- Existing HVAC repairs – Keep in mind that existing HVAC boxes almost always require minor repairs at the least. Generally speaking, the older a building is, the more costly the repairs tend to be.

6) Stay plugged in.

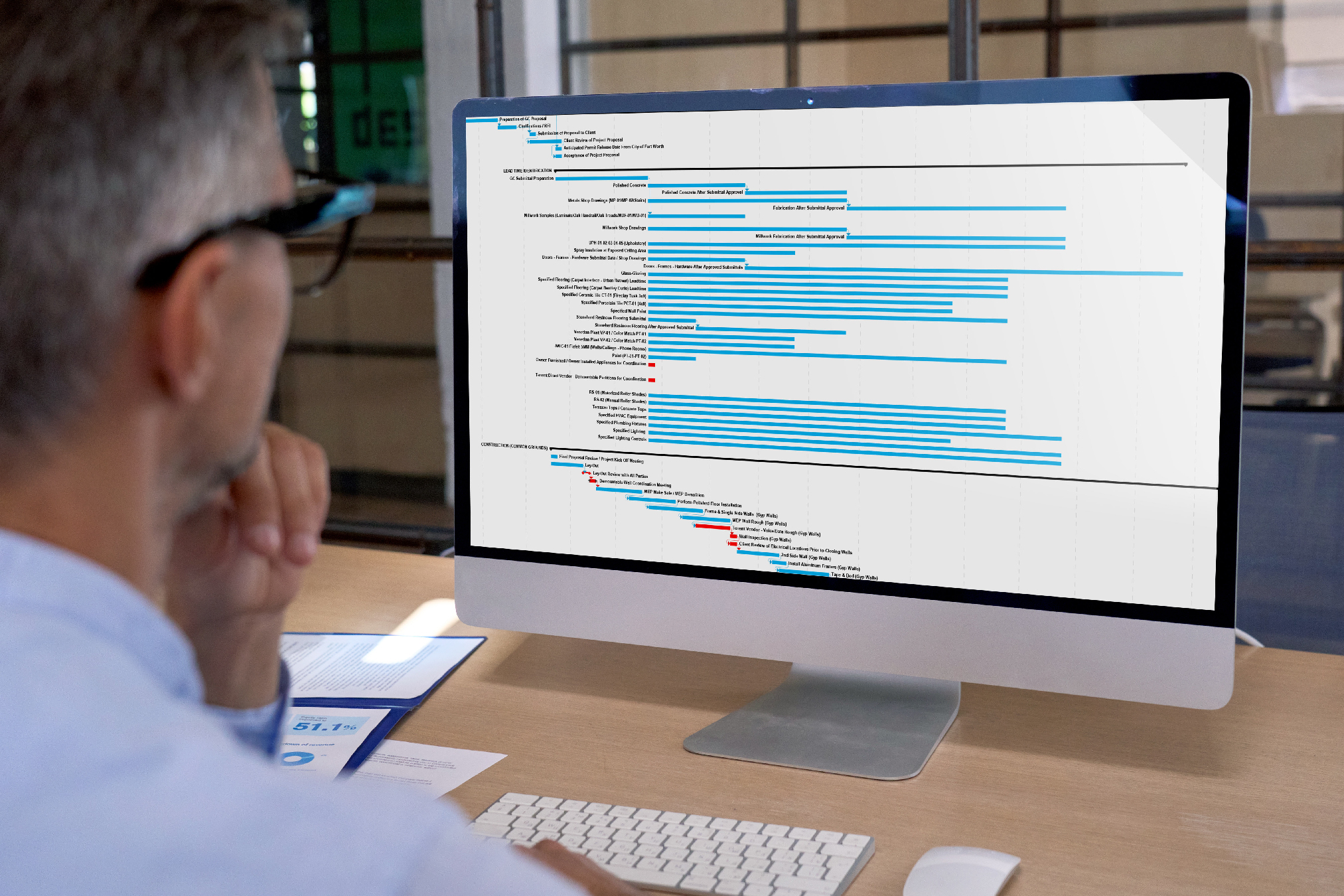

Stay actively involved each step of the way and see how your project tracks against the schedule in real-time. Attending weekly meetings and regularly visiting the site are great ways to stay plugged in.

7) Discuss expectations and timing with the design team.

Regular and open communication with the design team is imperative to make sure everyone is on the same page regarding submittal approval timing. Architects generally prefer to have at least two weeks to review but many times, submittals need to be reviewed faster.

8) Always have backups.

Preparing alternatives can help ensure you stay on schedule in case of supply chain shortages or increased prices. Below are two important areas we recommend you have backups ready:

- Materials and fixtures – Deciding which materials and fixtures are okay to substitute versus the ones you can’t live without helps the entire team know how to pivot if something isn’t available or lead times are extended.

- Value engineering alternates – Provide value engineering alternates you are comfortable with in the schematic design and design development phases to avoid scrambling for savings at the last minute. Providing these options allows the team to better understand the overall project budget and stay on track.